How to Choose the Right Electric Ball Valves for Your Needs?

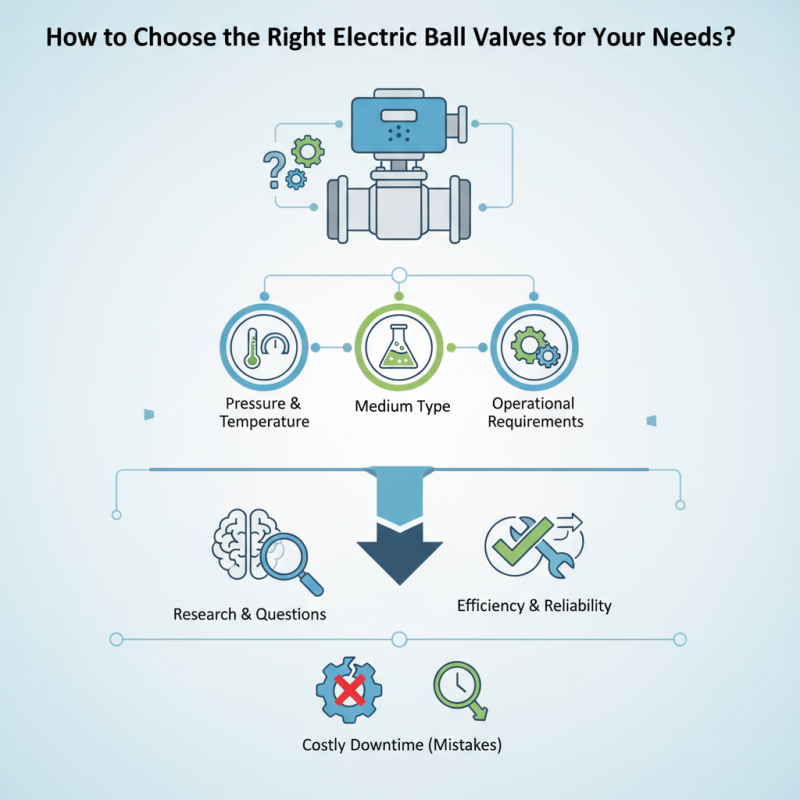

Choosing the right Electric Ball Valves can seem overwhelming. These devices play a crucial role in controlling fluid flow. Their efficiency directly impacts industrial processes.

Electric Ball Valves come in various sizes and configurations. Selecting the right type depends on your specific application. You must consider factors such as pressure, temperature, and medium. It’s essential to identify the operational requirements clearly.

Mistakes in choosing Electric Ball Valves can lead to costly downtime. Understanding specifications can be complex. However, doing thorough research and asking the right questions can help simplify the process. This choice can make a significant difference in efficiency and reliability in the long run.

Understanding Electric Ball Valves and Their Applications

Electric ball valves are essential in various industries. They provide quick and reliable control over fluid flow. Understanding their construction and operation is vital for selecting the right one. Electric ball valves typically feature a spherical disc, which controls flow by rotating 90 degrees. This design allows for tight sealing and minimal pressure drop.

Applications for electric ball valves vary widely. In the HVAC sector, they regulate heating and cooling systems. According to a recent market study, the HVAC segment alone is expected to reach $100 billion by 2025. In the water treatment industry, these valves manage wastewater systems. The demand here is growing, with a projected increase of 6% annually.

However, choosing the right valve can be tricky. Not every valve suits every application. Some may not withstand harsh environments. This leads to potential failures. It's essential to consider factors like fluid type, temperature, and pressure. Industry data indicates that approximately 30% of valve failures result from improper selection. Therefore, understanding your specific needs is critical.

Factors to Consider When Selecting Electric Ball Valves

When selecting electric ball valves, several key factors warrant attention. First, consider the application requirements. The pressure and temperature must match the valve specifications. A report from the Global Market Insights states that industrial applications account for approximately 45% of electric valve demand. Understanding your system’s conditions is critical.

Next, think about the control type. Many options exist: on/off control, modulating control, and more. Each type serves different needs. For example, modulating control allows for precise flow regulation. According to industry data, more than 30% of users prefer this for energy efficiency.

Finally, assess the material compatibility. Electric ball valves are made from various materials like brass, stainless steel, or PVC. Choosing the right material impacts durability and performance. A mismatch can lead to leaks or failures. Regular maintenance can help, but it may not eliminate all risks. Always ask an expert if unsure. This careful consideration ensures optimal performance and longevity of your valve system.

How to Choose the Right Electric Ball Valves for Your Needs? - Factors to Consider When Selecting Electric Ball Valves

| Feature | Importance | Recommended Specification |

|---|---|---|

| Valve Size | Critical for flow control | Depends on pipeline dimensions |

| Material | Affects durability and chemical compatibility | Stainless steel or PVC |

| Operating Voltage | Compatibility with existing systems | 24V or 220V |

| Actuator Type | Influences speed and control | Electric with position feedback |

| IP Rating | Protection against dust and water | IP65 or higher |

| Temperature Range | Ensures operation within limits | -10°C to 80°C |

| Flow Coefficient (Cv) | Determines flow capacity | As per application requirements |

| Control Type | Direct or remote control capabilities | On/off or modulating |

Comparing Different Types of Electric Ball Valves

When choosing electric ball valves, consider the different types available. Actuator styles vary significantly. Some are electric, while others are pneumatic. Each type has its own advantages. Electric valves offer precise control. They respond quickly to signals. Pneumatic options are often faster but may require more maintenance.

Another factor is the material construction. Stainless steel valves resist corrosion better than plastic varieties. However, plastic might be lighter and cheaper. The choice often depends on the specific application. For example, food industries often prefer stainless steel. It’s crucial to evaluate the environment in which the valve will operate. High temperatures or aggressive chemicals can influence your decision.

Lastly, don’t overlook power supply options. Some valves operate on AC power, while others use DC. The choice affects installation and compatibility. Consider space and access as well. If power supply is limited, that could be a significant drawback. Assessing these details can guide you towards the right valve for your needs. Balancing cost, performance, and functionality is essential.

Comparison of Different Types of Electric Ball Valves

Evaluating Specifications and Performance Features

When choosing electric ball valves, evaluating specifications is crucial. Start by examining the valve material. Common options include brass, stainless steel, and plastic. Each material has its strengths and weaknesses. Brass, for example, is durable but can corrode. Plastic offers resistance to chemicals but may not withstand high pressures. Knowing your environment is key.

Next, look at performance features. The valve's flow rate and pressure rating determine its suitability for your application. Higher flow rates often mean quicker processes, but they can also lead to noise and wear. Additionally, consider the valve's response time. A quicker response can improve system efficiency but might create challenges in sensitive applications.

Wattage and power supply are also essential. Ensure compatibility with your existing systems. Overloading can cause damage or failure. Sometimes, specifications can seem overwhelming. It’s easy to miss vital details when rushing. Take time to reflect on what your project truly needs. Balancing cost with quality can be tricky. It’s wise to compare options carefully.

Installation and Maintenance Tips for Electric Ball Valves

Electric ball valves are crucial for many applications. Proper installation is vital. Ensure all connections are tight. Incorrect wiring can lead to malfunctions. Follow the manufacturer’s instructions carefully. Check that the power supply is stable. Unstable power can cause the valve to behave erratically.

Once installed, regular maintenance is essential. Schedule routine checks every few months. Look for leaks or unusual noises. These issues can indicate deeper problems. Lubricate moving parts as needed. This prevents wear and tear over time. Visual inspections help catch problems early.

Consider environmental factors too. Humidity and temperature fluctuations can affect performance. Protect valves from harsh conditions when possible. Failures often come from neglecting these details. Sometimes, you might overlook small signs of wear. Reflect on your maintenance schedule and improve it.