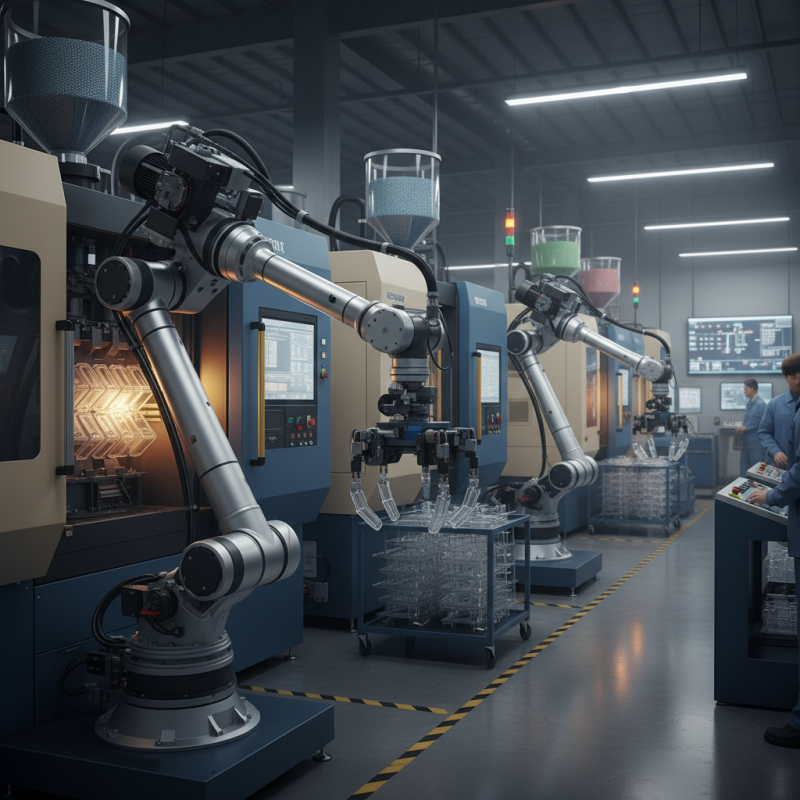

How to Choose the Right Injection Machine Robot for Your Needs?

Choosing the right Injection Machine Robot is crucial for your manufacturing process. The right robot can enhance efficiency and precision. However, selecting one can be daunting. Many options exist, and each machine has unique features.

Think about specific needs. Are you focusing on speed, accuracy, or versatility? Assess your production line. It may be inefficient to rush this decision. Consider the type of materials you'll be working with too. Some robots are better suited for certain applications than others.

Remember, not every Injection Machine Robot will meet your requirements. Conduct thorough research and reflect on your choices. By investing time upfront, you will likely avoid issues later. A well-chosen robot can lead to significant gains in productivity and quality.

Key Factors to Consider When Selecting an Injection Machine Robot

Choosing the right injection machine robot can be challenging. It’s vital to consider several key factors. The type of materials being processed greatly influences robot selection. For instance, thermoplastics require different handling than thermosets. According to a recent industry report, 70% of production failures are linked to material mishandling.

Robot payload capacity is another critical aspect. A robot should handle the weight of the machinery and the parts. Overburdening may lead to damages or malfunctions. An analysis revealed that a 20% increase in load can reduce a robot's lifespan by 30%.

Flexibility is essential in production environments. Robots that can adapt to various tasks ensure long-term usability. However, higher flexibility doesn't always mean better performance. Some machines struggle with both rigidity and adaptability. Evaluating specific needs can prevent costly mistakes. Balancing these factors with budget constraints is crucial. Be aware of hidden costs in maintenance and energy consumption.

Understanding Different Types of Injection Robots and Their Applications

When selecting an injection machine robot, understanding the various types and their applications is crucial. For example, there are three primary categories: Cartesian robots, SCARA robots, and six-axis robots. Each has unique advantages. Cartesian robots offer precision, great for linear tasks. SCARA robots excel in horizontal movements and assembly operations. Six-axis robots are more flexible, handling complex tasks efficiently.

Industry reports indicate that the global injection molding robot market is projected to reach approximately $3 billion by 2025. This growth is driven by the increasing demand for automation in manufacturing. Companies seek to enhance productivity and reduce labor costs. Choosing the right robot can significantly impact these objectives.

Tip: Assess your specific needs before making a decision. Consider factors such as workspace, weight capacity, and required precision. It’s important to weigh costs against the benefits of increased efficiency. Moreover, not every robot will suit every process. Always reflect on your production goals and select accordingly.

Evaluating Payload Capacity and Reach for Optimal Performance

When selecting an injection machine robot, evaluating payload capacity and reach is crucial for optimal performance. Payload capacity refers to the weight the robot can handle. Most industrial robots can manage anywhere from a few kilograms to over 1,000 kilograms depending on the type and design. Understanding your production needs is key. If you require heavy lifting for larger injection molds, ensure that the robot's capacity meets these demands.

Reach defines how far the robot can extend its arm. This is important for maneuverability within your workspace. For applications with tight spaces, a shorter reach may suffice. However, larger operations may need robots with extended reach to cover more area efficiently. Data from industry studies show nearly 60% of businesses have faced downtime due to improper reach settings.

Tip: Always assess your workspace layout before selecting a robot. Mapping out the required movements can prevent costly mistakes.

It's worth noting that a robot's capabilities often exceed the actual demands of a task, leading to wasted resources. Careful evaluation is necessary to avoid choosing a robot that may solve one issue but create another. Pay attention to potential trade-offs in speed versus payload capacity, as a heavier load might reduce cycle times.

Assessing the Importance of Speed and Precision in Injection Robots

Speed and precision are critical factors when selecting an injection machine robot. A recent industry report indicates that precision in manufacturing processes can improve overall efficiency by up to 30%. This indicates that investing in high-precision robots may yield significant returns. Speed is also essential; robots that operate faster can reduce cycle times and increase productivity. Research shows that a 10% increase in speed can lead to a 15% boost in production output.

However, balancing speed and precision presents challenges. Highly precise machines may operate more slowly to maintain accuracy, while faster machines might compromise on quality. Manufacturers must assess their specific needs carefully. An injection robot that meets high-speed requirements may not always deliver the same level of detail. Therefore, understanding the trade-offs is crucial for making an informed choice.

Industries vary in their priorities. For high-volume production, speed might take precedence. For applications requiring intricate designs, precision could be more important. A report by the International Association of Automation highlighted that nearly 40% of companies struggle with this balance. As the industry evolves, companies must reflect on their capabilities and future needs when selecting an injection machine robot.

Analyzing Cost, Return on Investment, and Total Cost of Ownership

When selecting an injection machine robot, understanding costs is crucial. Initial purchase costs can be high. Consider your budget carefully. What seems affordable now might not be so later. Maintenance and repair costs can add up quickly. Regular upkeep is necessary. Neglecting this can lead to bigger issues down the line.

Calculating the return on investment (ROI) is essential. Think about productivity gains. A robot can increase efficiency. But, if it breaks down often, your ROI may dwindle. Look at machine durability. Some robots promise longevity but may not deliver. Researching user experiences can provide valuable insights.

Total cost of ownership (TCO) encompasses more than just upfront costs. Factor in energy consumption. An energy-efficient model might save you money over time. Training staff on new technology also adds to TCO. A steep learning curve can hinder operations initially. Budget for potential downtime as well; it can be costly. Ultimately, weighing these factors will guide you in choosing the right machine.

How to Choose the Right Injection Machine Robot for Your Needs?

| Dimension | Description | Estimated Cost ($) | Return on Investment (%) | Total Cost of Ownership ($) |

|---|---|---|---|---|

| Robot Arm Type | 6-Axis Robotic Arm | 15,000 | 25 | 35,000 |

| Payload Capacity | 5 kg | 10,000 | 20 | 30,000 |

| Cycle Time | 0.8 seconds | 12,000 | 30 | 25,000 |

| Programming Language | Python | 8,000 | 35 | 20,000 |

| Warranty Period | 2 Years | 5,000 | 15 | 10,000 |